Sewage Disposal Plant at Kew Beach, Toronto, Ont.

By C. H. Rust, City Engineer

Municipal Engineering, November 1907, Vol. XXXIII No. 5, pg. 315 Municipal Engineering Company Indianapolis and New York.

That portion of known as the city of Toronto, Ont. known as Kew Beach is situated at the eastern limit on the shore of Lake Ontario and is solely a residential district. The level of the ground is only a few feet above the level of the lake and the soil sandy underlaid with clay. The property owners have been for some time asking for drainage, but owing to the municipality of East Toronto procuring their water supply from a point about three-quarters of a mile east of this district, and to the objection of the Board of Health to allowing crude sewage to be deposited in the lake, it was necessary to adopt the sewers and purification works as described. The drainage area of this district is one hundred and eight-five acres, containing a population of approximately 10,000 during the summer months.

To ascertain the consumption of water a meter was placed upon this district and it was found that the actual consumption per head in twenty-four hours was 16 gallons.

The main sewer is laid along the Lake front at a depth varying from 2 to 9 feet below the lake level and is constructed of 16 and 10 inch cast iron socket pipes. All sewers from the north discharge into this sewer and at a point midway between the outfall and the summit is constructed pumping station No. 1, raising the sewage from the low level sewers from the east and north into the high level sewer which gravitates to No. 2 pumping station where the sewage is raised into the works. These pumping stations are constructed of concrete and are circular in plan with a partition wall in the centre and have a reservoir space of 3,200 gallons; and each contains a duplicate set of pumps and motors, No. 1 consisting of two 5 h. p. alternating vertical motors and two 4-inch submerged centrifugal pimps and No. 2 consisting of two 7 1/2 h. p. alternating vertical and two 4-inch submerged centrifugal pumps. Motors and pumps are automatically controlled by the and fall of the sewage in the reservoir.

The shafts of the pumps are connected direct onto the armature of the motors without any bevel gearing, which eliminates all noise whilst practically operating.

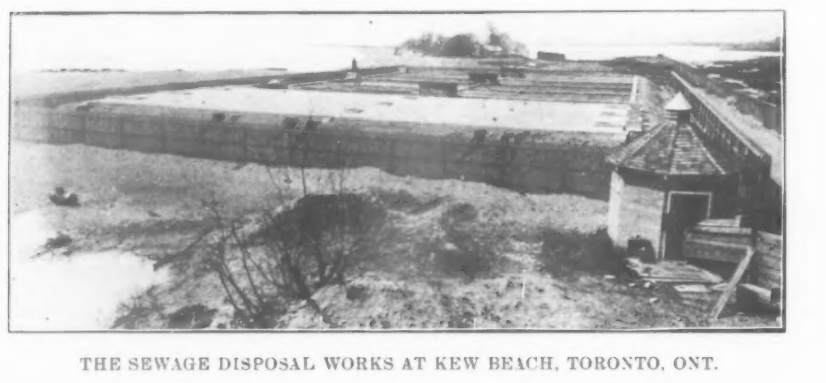

The disposal works consist of three septic tanks and twelve bacteria beds, constructed from plans designated by the Cameron Septic Tank Company and operated by the gear patented by them.

The works are erected on the shore of the lake about 200 feet from the water’s edge, and are supported by 10-inch piles driven 16 feet through the sand and into the hard clay and surrounded by tongued and grooved sheet piling driven fourteen feet. The construction of these works is of concrete in the proportion of seven of broken stone and sand to one of cement.

The three septic tanks are each 100 ft. x 14 ft. x7 ft. 3 in. deep at the low end with a total capacity of 183,750 gallons. They are covered with a 3-inch concrete roof, made in the proportions of 4 1/2 of broken stone and sand to one of cement and reinforced with 3-inch mesh, 10-gauge expanded metal. At 6 ft. 6 in. centres are 9×6 beams supporting the roof, reinforced with 3/4-inch Johnson’s corrugated steel bars. An inlet channel feeds the three tanks at the high inch concrete end, each one of which can be operated independently from this channel.

The distribution of sewage into the tanks takes place through one 8-inch pipe, thence through four 12-inch openings, 3 feet above the bottom of the tank, which accomplishes a maximum flow of sewage with a minimum amount of disturbance. At the low end of the tanks thirteen 4-inch outlet pipes are built into the wall, 2 ft. 7 in. below the water line, connecting with the cleansing chamber and outlet channel. From here the main effluent carrier is built into the wall of the bacteria beds in line with the outlet channel of the septic tanks and runs the whole length to the end of the beds and has three branches at regular’ intervals, each feeding one set of 4 beds.

There are 12 bacteria beds, 3 sets of 4 having a 1,860 square yards. Each bed is 50 ft x 28 ft. x 4 ft. 6 in. deep and is filled 4 feet deep with furnace slag vary size from 1/4 -inch to 1 1/2 inches. On the floor is laid 14 lines of 3-inch weeping tile collectors, discharging into a 9-inch main collector, and 6 inches below the surface of the slag are 6 lines of 6-inch weeping tile distributers fed by a 9-inch main distributer. All discharge pipes terminate in one common chamber from which a 15-inch main filtrate carrier is laid down to the lake, at the last 30 feet being supported on piles.

The sewage is raised to a height of 22.5 feet at pumping station No. 2 into the inlet channel, which is below water line and extends to a point beyond the inlet to septic tank No. 3. From this inlet channel the sewage is admitted into each tank required to be operated through the submerged openings.

The effluent from the tanks flows through the submerged outlets and through the effluent chamber, which arrests any solid matter which may find its way through the outlet pipes in time of excessive flow and thence into the outlet channel.

The semi-clarified sewage not flows along the main effluent carrier an on to the automatic distributing gear from which it is distributed to each bed in turn through its admission valve. The discharge valve will be close meanwhile so that the interstices of the filtering materials will be filled with the tank effluent. The effluent remains in the contact beds for a period of about two hours, according to the rate of flow. The discharge valve will then open, when the filtered effluent escapes, drawing down after it a supply of air into every crevice of the contact bed. The latter will then drain and aerate whilst the remaining contact beds of the set are filling, after which it will again be filled in turn. This method of working renders the contact beds self-cleaning so that they retain their purifying power unimpaired.

The alternate filling and emptying of the contact beds is affected automatically by means of the alternating gear in the following manner: As soon as bed No. 1 is filled, a small quantities of filtered effluent overflows from it’s discharge well into a float chamber, lifting the float, at the same time opening the admission valve and closing the discharge valve of bed No. 2. When bed No. 2 is filled, this operation is repeated, the flow of the tank effluent is diverted into bed No. 3 and the discharge valve of bed No. 1 is opened and its contents are allowed to discharge.

The construction involved the carrying out of 12,262 feet of 9-inch pipe; 1,569 feet of 12-inch; 1,349 feet of 15-inch; 2,451 feet of cast iron pipe, 32 manholes and 982 junctions. The average depth of the sewers was 8 feet 9 inches. A great deal of the work was in sand charges with water involving constant pumping.

The cost of the works was as follows:

| Sewers and pumping stations | $37,755 |

| Pumping plant | 3,185 |

| Disposal works | 13,079 |

| Piling, etc. | 5,119 |

| Slag, 2,500 cu. yrds. at $1.50 | 3,750 |

| Automatic distributing gear | 4,000 |

| $66,888 |

It was found after the slag had been in the beds some time about ten per cent. of the settlement tool place. The works have been in operation since April and the effluent so far has been very satisfactory.